World Best of Shock Absorbers & Buffers

KSA Series

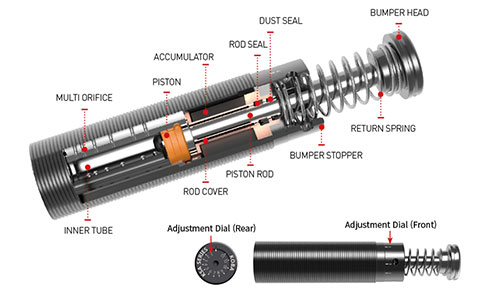

When the object collides, the shock absorber piston rod is pushed into the body, and the oil moves to the oil chamber through the groove formed along the outskirt of the inner tube. During this process, kinetic energy is transformed into heat energy and dissipates into the atmosphere, resulting in damping force. When the load is removed, the Piston Rod is returns to its original position by the compressed power of return spring. Middle pistion adjustment dial is one of the feature.

- Depending on the collision speed, you can fit the buffer dial from 0 to 300 degrees in 12 steps.

- Adjustment is easy in various installation environment by adopting front and rear adjustmenet dial.

- Shock Absorber Body is built as one body, not only robust but also fundamentally sovles the trouble so called bottom out problem.

- Because of full threaded body KMS Series is easy to be installed and precise location fixing is possible. And surface area is increased to dissipate thermal energy fast to atmosphere.

- Piston rod is made of anticorrosion material and rod cover is made of long lasting material with function of seal protection and that enable to guarantee long life.

- Body surface is electroless Ni plated or alloy plated, so that strong to corrosion.

- By using Urethane Cap, noise can be reduced.

- Velocity ranges : 0.3~5.0m/s

- Temperature ranges : -10~80℃

- Special specification custom made : Can be made to order according to characteristics such as thead, stainless, low temperature and high temperature.

: Option -40~120℃(Special oil and seal)

| MORE VIEW | Model | Stroke (mm) St | Max.Energy / Cycle (Nm) ET | Max.Energy / Hour (Nm/h) ETC | Effective Weight (kg) me | Recoil Force (N) | Weight (g) | Thread | |

| Ext | Comp | ||||||||

| KSA45-25 | KSA45-25 | 25 | 650 | 195,000 | 50-13,354 | 49.7 | 82.8 | 1.13 | M45X1.5 |

| -50 | 50 | 1,300 | 260,000 | 99-26,700 | 45.6 | 84 | 1.3 | ||

| -75 | 75 | 2,000 | 300,000 | 148-39,060 | 44.3 | 86.3 | 1.52 | ||

| KSA64-25 | KSA64-25 | 25 | 1,250 | 152,000 | 92-24,400 | 61.8 | 110 | 2.9 | M64X2.0 |

| -50 | 50 | 2,500 | 248,000 | 185-48,800 | 60.8 | 133.2 | 3.3 | ||

| -75 | 75 | 3,750 | 265,000 | 277-73,240 | 61.4 | 148.3 | 3.8 | ||

| -100 | 100 | 5,000 | 360,000 | 370-97,650 | 59.4 | 160.1 | 4 | ||

| -125 | 125 | 6,250 | 413,000 | 462-122,000 | 57.1 | 160.4 | 7.7 | ||

| -150 | 150 | 7,500 | 450,000 | 555-146,480 | 51 | 166.8 | 8.9 | ||

| KSA85-25 | KSA85-25 | 25 | 2,000 | 330,000 | 148-39,600 | 132 | 245.8 | 12.2 | M85X2.0 |

| -50 | 50 | 4,000 | 462,000 | 296-78,100 | 131.6 | 271.7 | 14.4 | ||

| -75 | 75 | 6,000 | 680,000 | 444-117,200 | 130 | 325.1 | 17 | ||

| -100 | 100 | 8,000 | 825,000 | 591-156,300 | 125.4 | 327.7 | 20 | ||

| -125 | 125 | 10,000 | 859,000 | 740-195,300 | 126.6 | 343.3 | 23.6 | ||

| -150 | 150 | 12,000 | 901,000 | 930-220,300 | 126.6 | 386.7 | 28 | ||

Model selection

Model selection Contact

Contact